-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

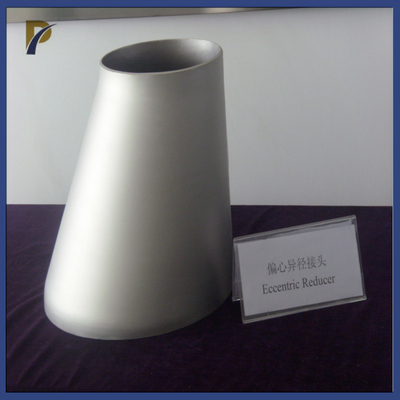

ASME B16.9 GR1 GR2 GR5 Titanium Reducer DN150 / 125 Titanium Concentric Reducer

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Titanium Reducer | Type | Concentric Reducer/Eccentric Reducer |

|---|---|---|---|

| Grade | TA1,TA2,TC4,TA10GR1,GR2,GR5,Gr12 | Size | DN150/125,DN125/100,DN125/80,DN100/65 Etc. |

| Standard | ASME B16.9 | Surface | Bright, Pickled, Sandblasted |

| Highlight | Pickled Titanium Concentric Reducer,GR5 Titanium Reducer,DN150 Titanium Concentric Reducer |

||

Titanium Reducer

1. Information Of Titanium Reducer.

| Name | Titanium Reducer | |

| Type | Concentric Reducer/Eccentric reducer | |

| Grade | TA1,TA2,TC4,TA10GR1,GR2,GR5,Gr12 or according to customer | |

| Size | DN150/125,DN125/100,DN125/80,DN100/65 etc. Or custom as per drawing. | |

| Standard | ASME B16.9,GB/T 27684,GB/T 12459 | |

| Surface | Bright, pickled, sandblasted | |

| Payment | T/T,Paypal | |

| MOQ | 1pc |

Titanium reducer, also called titanium reducer, is used to connect two different pipe diameters. Titanium reducers are divided into concentric titanium reducers and eccentric titanium reducers according to their form and shape.

2. Size of Titanium Reducer.

| NPS | DN |

D (Outdiameter) |

SCH5s | SCH10s | SCH10 | SCH20 | SCH30 | STD | SCH40 | SCH40s |

| 1/2" | 15 | 21.3 | 1.65 | 2.11 | 2.11 | 2.41 | 2.77 | 2.77 | 2.77 | |

| 3/4" | 20 | 26.7 | 1.65 | 2.11 | 2.11 | 2.41 | 2.87 | 2.87 | 2.87 | |

| 1" | 25 | 33.4 | 1.65 | 2.77 | 2.77 | 2.9 | 3.38 | 3.38 | 3.38 | |

| 1-1/4" | 32 | 42.2 | 1.65 | 2.77 | 2.77 | 2.97 | 3.56 | 3.56 | 3.56 | |

| 1-1/2" | 40 | 48.3 | 1.65 | 2.77 | 2.77 | 3.18 | 3.68 | 3.68 | 3.68 | |

| 2" | 50 | 60.3 | 1.65 | 2.77 | 2.77 | 3.18 | 3.91 | 3.91 | 3.91 | |

| 2-1/2" | 65 | 73 | 2.11 | 3.05 | 3.05 | 4.78 | 5.16 | 5.16 | 5.16 | |

| 3" | 80 | 88.9 | 2.11 | 3.05 | 3.05 | 4.78 | 5.49 | 5.49 | 5.49 | |

| 3-1/2" | 90 | 101.6 | 2.11 | 3.05 | 3.05 | 4.78 | 5.74 | 5.74 | 5.74 | |

| 4" | 100 | 114.3 | 2.11 | 3.05 | 3.05 | 4.78 | 6.02 | 6.02 | 6.02 | |

| 5" | 125 | 141.3 | 2.77 | 3.4 | 3.4 | 6.55 | 6.55 | 6.55 | ||

| 6" | 150 | 168.3 | 2.77 | 3.4 | 3.4 | 7.11 | 7.11 | 7.11 | ||

| 8" | 200 | 219.1 | 2.77 | 3.76 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 |

| 10" | 250 | 273 | 3.40 | 4.19 | 4.19 | 6.35 | 7.8 | 9.27 | 9.27 | 9.27 |

| 12" | 300 | 323.8 | 3.96 | 4.57 | 4.57 | 6.35 | 8.38 | 9.53 | 10.31 | 9.53 |

| 14" | 350 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | |

| 16" | 400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | |

| 18" | 450 | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | |

| 20" | 500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | |

| 22" | 550 | 558.8 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 9.53 | ||

| 24" | 600 | 609.6 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | |

| 26" | 650 | 660.4 | 7.92 | 12.7 | 9.53 | |||||

| 28" | 700 | 711.2 | 7.92 | 12.7 | 15.88 | 9.53 | ||||

| 30" | 750 | 762 | 6.35 | 7.92 | 7.92 | 12.7 | 15.88 | 9.53 | ||

| 32" | 800 | 812.8 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | |||

| 34" | 850 | 863.6 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | |||

| 36" | 900 | 914.4 | 7.92 | 12.7 | 15.88 | 9.53 | 19.05 | |||

| 38" | 950 | 965.2 | 9.53 | |||||||

| 40" | 1000 | 1016 | 9.53 | |||||||

| 42" | 1050 | 1066.8 | 9.53 | |||||||

| 44" | 1100 | 1117.6 | 9.53 | |||||||

| 46" | 1150 | 1168.4 | 9.53 | |||||||

| 48" | 1200 | 1219.2 | 9.53 |

3. Production Process of Titanium Reducer.

Reducer (big and small head) is a pipe fitting used at the pipe diameter reduction point. The commonly used forming processes are reducing diameter pressing, expanding diameter pressing or reducing diameter plus expanding diameter pressing. For certain specifications of reducers, stamping can also be used. The reduction forming process of the reducer is to put a tube with the same diameter as the large end of the reducer into the forming mold, and by pressing along the axial direction of the tube, the metal moves along the mold cavity and shrinks to form. According to the diameter reduction of the guide tube, it is divided into one-time pressing forming or multiple pressing forming.

![]()

![]()

Company Profile:

Shaanxi Peakrise Metal Co., Ltd. is an rich experienced tungsten,molybdenum, tantalum, niobium, titanium,zirconium,nickel non-ferrous metal production enterprise,main products include tungsten-copper alloy, molybdenum-copper alloy, tungsten-molybdenum alloy, high specific gravity tungsten alloy, tantalum alloy,niobium alloy,titanium alloy and other more than 100 kinds of products.we have more than 13 years of rich production experience and export experience, and solve related import and export problems for customers. , one-stop solution to all difficulties.Products are exported to Taiwan, Ukraine, South Korea, the United States, Australia, Germany, Iran and other countries, and have established long-term good cooperative relations with customers. Our products are highly recognized and evaluated by customers.

Please click below button for learn more our products.

![]()