-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

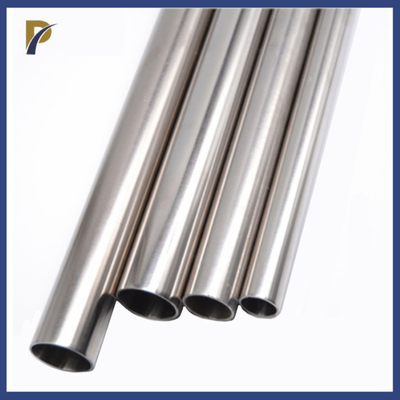

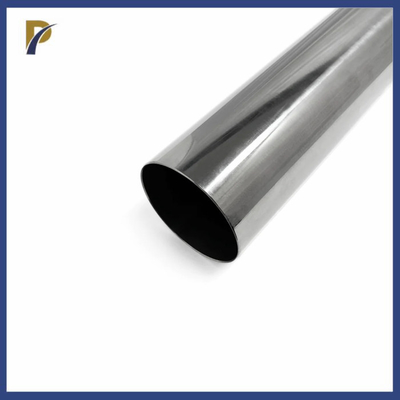

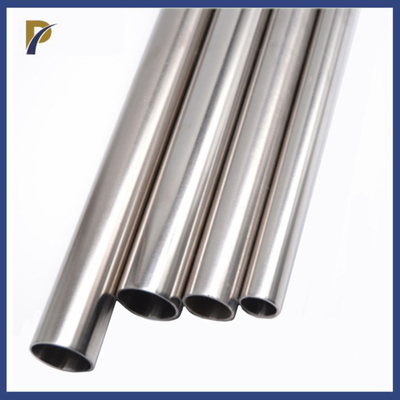

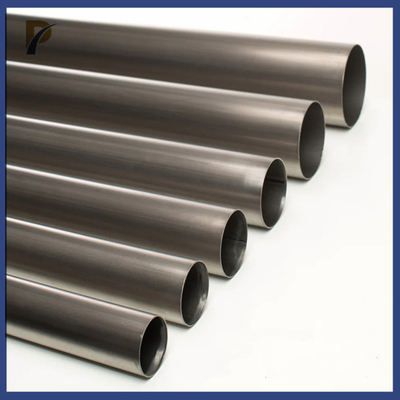

Zr Pipes R60702 Zirconium Tube Specialty Application Pure Polished Explosion-Proof Tube

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Zr Pipes R60702 Zirconium Tube Specialty Application Pure Polished Explosion-Proof Tube | Material | Zirconium & Zirconium Alloy |

|---|---|---|---|

| Grade | Zr702,Zr704,Zr705,Zr60001 Etc. | Purity | >99.2% |

| Diameter | 6-127mm | Wall Thickness | 0.5-4.5mm |

| Length | 500-10000mm | Delivery | Annealed |

| Highlight | Explosion-Proof Zirconium Tube,Specialty Application Zirconium Tube,Pure Polished Zirconium Tube |

||

Product Information:

| Name: | Zr Pipes R60702 Zirconium Tube Specialty Application Pure Polished Explosion-Proof Tube |

| Grade: | Zr2 Zr4 Zr702 Zr705 Zr60804 Zr60001 Zr60901 |

| Density: | 6.51g/cm3 |

| Size: | OD 6-127mm,WT 0.5-4.5mm,L <10meters Or process according to customer's request. |

| Standard: | ASTM B523 ASTM B658,ASTM B353 |

| Main process: | Preparation of consumable electrodes, casting, forging, hot extrusion (tube blank), cold working and finishing. |

| Status: | Annealing (M) Hot working status (R) Cold working status (Y) Annealing |

| Surface: | Rolled surface, polished surface, polished surface, pickled metal surface |

![]()

![]()

| Grade | Element composition(%)< | Standard | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | ||

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 | ASTM B658 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- | |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 | |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 | |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 | |

| R60804 | 97.5 | 0.01 | 0.25~0.37 | 1.2~1.7 | 0.0025 | 0.008 | 0.027 | -- | 0.09~0.16 | ASTM B353 |

| R60001 | 99.9 | 0.01 | 0.17 | 0.005 | 0.0025 | 0.008 | 0.027 | -- | -- | |

![]()

![]()

Why Choose Us:

1). Reliable quality, but competitive price

2). Rich experience in rolling process

3). Comprehensive and advanced production facility

4). Customer-oriented service

Package & Shipping

![]()

![]()

Company Profile:

![]()

Shaanxi Peakrise Metal Co., Ltd. is an rich experienced tungsten,molybdenum, tantalum, niobium, titanium,zirconium,nickel non-ferrous metal production enterprise,Products are exported to Taiwan, Ukraine, South Korea, the United States, Australia, Germany, Iran and other countries, and have established long-term good cooperative relations with customers. Our products are highly recognized and evaluated by customers.has a variety of production equipment, such as intermediate frequency sintering furnace, vacuum arc melting furnace, laser cutter,plasma electron beam melting furnace, vacuum annealing furnace, various rolling mills, wire drawing machines, plasma welding rooms, lathes, milling machines, sawing machines, drilling machines, Shears, Stamping Equipment, Cutting Equipment, Grinders, Straightening Machines, CNC, etc.

For know more our product information

![]()