-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

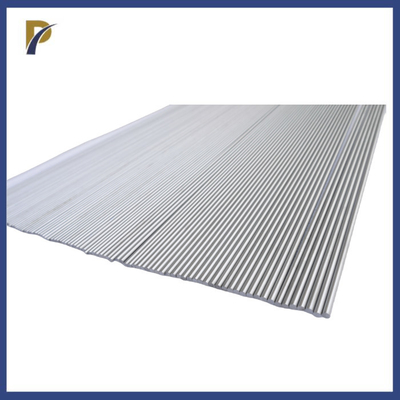

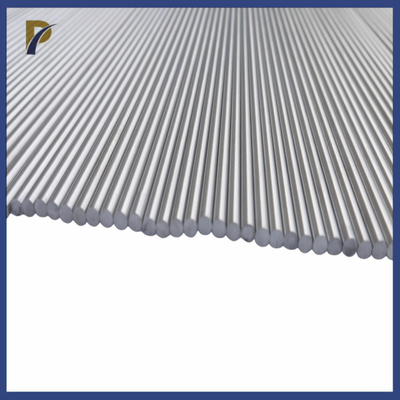

Electric Light Source Molybdenum Rod with High Melting Point ASTM B387 Standard

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Electric Light Source Molybdenum Rod With High Melting Point | Material | Molybdenum & Molybdenum Alloy |

|---|---|---|---|

| Grade | Mo1 MoLa TZM | Diameter | Diameter 5-100mm |

| Length | ≤2500mm | Surface | Black,Polished |

| Purity | >99.97% | Standard | ASTM B387 |

| Highlight | High Melting Point Molybdenum Rod,Electric Light Source Molybdenum Rod,ASTM B387 Molybdenum Rod |

||

Molybdenum rods have high melting point, good thermal conductivity and low thermal expansion performance. They can be used to manufacture electric vacuum devices and electric light source parts. They can also be used as high-temperature heating elements and high-temperature structural parts, electrodes, etc.

Molybdenum rod

Grade: Mo1,MoLa,TZM,MoW alloy

Density: 10.2g/cm3

Purity: >99.97%

Diameter: 4-120mm

Length: <3000mm

Surface: Polished

Appearance: No oil stain, no pits, no cracks, no flaws, smooth and bright.

Standard: ASTM B387

| Molybdenum Melting Glass Molybdenum Electrode | |||||

| Dia [mm] |

tolerance [mm] |

length [mm] |

Surface | Straightness [per m] |

Approx weight [kg/m] |

| 4.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.128 |

| 10.00 | +/- 0.020 | 1000 - 2000 | polished | <2.0 | 0.801 |

| 20.00 | +/- 0.020 | 2000 | polished | <2.5 | 3.204 |

| 25.00 | +/- 0.040 | 2000 | polished | <2.5 | 5.007 |

| 30.00 | +/- 0.300 | 2000 | Polished | <1.5 | 7.210 |

| 40.00 | +/- 0.300 | 2000 | Polished | <1.5 | 12.818 |

| 50.00 | +/- 0.400 | 2000 | Polished | <1.5 | 20.654 |

| 60.00 | +/- 0.400 | 2000 | Polished | <1.5 | 28.840 |

| 63.50 | +/- 0.400 | 2000 | Polished | <1.5 | 32.303 |

| 70.00 | +/- 0.400 | 2000 | Polished | <1.5 | 39.254 |

| 80.00 | +/- 1.000 | 2000 | Polished | <2.5 | 51.271 |

| 90.00 | +/- 1.000 | 2000 | Polished | <2.5 | 64.890 |

| 100.00 | +/- 1.000 | 2000 | Polished | <2.5 | 80.111 |

| 120.00 | +/- 2.000 | 2000 | Polished | <2.5 | 115.359 |

| ASTM B387 Standard | ||||||||

| C | O | N | Fe | Ni | Si | Al | Ca | Mg |

| max.0.01 | 0.007 | 0.002 | 0.01 | 0.005 | 0.01 | 0.002 | 0.002 | 0.002 |

Classification by material:

①Pure molybdenum rod: molybdenum content is greater than 99.95%.

②High-temperature molybdenum rod (molybdenum-lanthanum alloy rod): contains 0.4~1.2% lanthanum, and the molybdenum content is the remainder excluding impurities.

③TZM molybdenum rod: 0.4~0.6Ti, 0.07~0.12Zr, 0.01~0.05C.

Classification by surface state:

①Sintered molybdenum rod: the surface has a silver-gray metallic luster.

②Forged molybdenum rod: there is a layer of oxide on the surface, and the surface is black.

③Polished molybdenum rod: the surface has a metallic luster, flat and rough.

④Polished molybdenum rod: silver-gray metallic luster, smooth surface, small dimensional error

Molybdenum rod,Molybdenum plate,Molybdenum wire,Molybdenum tube,Molybdenum crucible,Molybdenum bolt screw and molybdenum process shape parts according to drawings.