-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

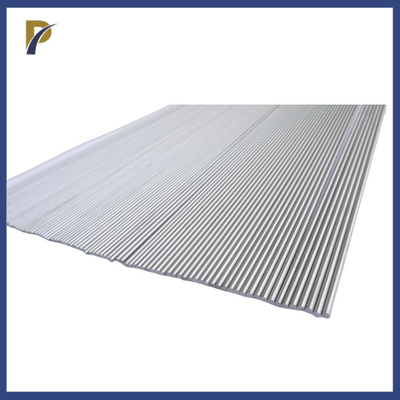

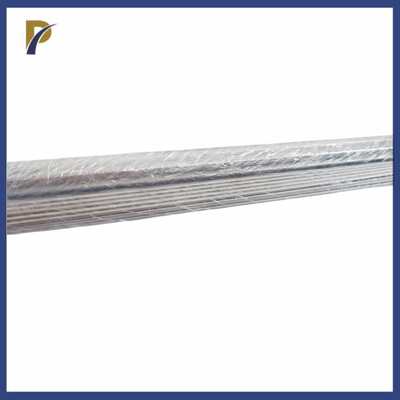

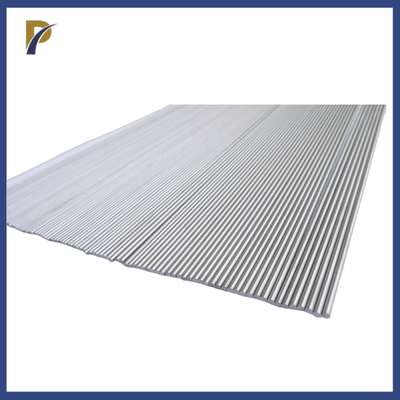

Electric Vacuum Device Molybdenum Rod With High-Temperature Resistance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Electric Vacuum Device Molybdenum Rod With High-Temperature Resistance | Material | Mo1,MoLa,TZM,MoW Alloy |

|---|---|---|---|

| Density | 10.2g/cm3 | Purity | 99.95%-99.97% |

| Shape | Round Bar | Diameter | 0.5-200 Mm |

| Length | 30 - 6000 Mm | Surface | Pickling, Polishing |

| Highlight | Electric Vacuum Device Molybdenum Rod,High Temperature Resistance Molybdenum Rod |

||

| Name | Diameter | Tolerance of diameter |

| Forged Mo rod | >80mm | +/-2.0mm |

| 25mm-80mm | +/-1.0mm | |

| swaging Mo rod | 10mm-25mm | +/-0.2mm |

| 3.0mm-10mm | +/-0.1mm | |

| Bright Mo rod | >20mm | +/-0.2mm |

| straighten Mo rod | 0.5mm-3.0mm | +/-0.03mm |

| Polished Mo rod | 0.8mm-50mm | +/-0.2mm |

Product advantages:

1).The recrystallization temperature is higher 1400℃~1500℃;

2).Elongated particulate structure for improved ductility;

3).Antioxidant is stronger;

4).Higher creep resistance.

Application:

Used to manufacture electric vacuum devices and electric light source parts.

Suitable for processing ion implantation parts.

Used as high-temperature heating elements and high-temperature structural parts.

Used as furnace electrodes in the glass and refractory fiber industries, working in 1300℃ glass solutions, with long service life.

Used as electrodes in the rare earth industry.