-

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

DavidGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation.

John MorrisMaterial experts, rigorous processing, timely discovery of problems in design drawings and communication with us, thoughtful service, reasonable price and good quality, I believe we will have more cooperation. -

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot.

JorgeThank you for your good after-sales service. Excellent expertise and technical support helped me a lot. -

PetraThrough very good communication all problems solved, satisfied with my purchase

PetraThrough very good communication all problems solved, satisfied with my purchase -

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

Adrian HayterThe goods purchased this time are very satisfied, the quality is very good, and the surface treatment is very good. I believe we will order the next order soon.

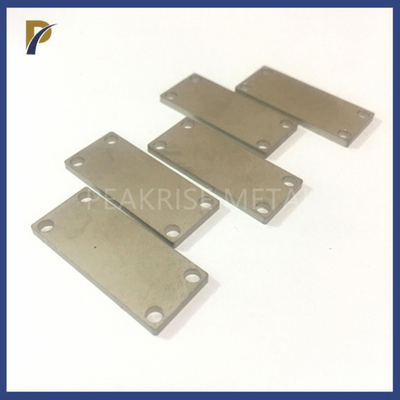

Custom Copper Molybdenum Microelectronic Material MoCu Alloy Electronic Package Sheet

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Application Of Molybdenum Copper Alloy As Microelectronic Material | Material | Molybdenum Copper Alloy |

|---|---|---|---|

| Grade | MoCu10,MoCu15,MoCu20,MoCu25,MoCu30,MoCu35 Etc. | Shape | Small Sheet Or Custom |

| Surface | Bright | Size | As Per Customer Request |

| Application | Microelectronic Materials Field | Export Port | Any Port In China |

| Highlight | Custom Microelectronic Material,Molybdenum Microelectronic Material,sintered molybdenum material |

||

Application Of Molybdenum Copper Alloy As Microelectronic Material

1. Description Of Molybdenum Copper Alloy As Microelectronic Material:

Molybdenum-copper alloy (MoCu a molybdenum-copper and tungsten-copper, both have low expansion characteristics (the thermal expansion coefficient of molybdenum is 5.0x10-6/℃, the thermal expansion coefficient of tungsten is 4.5x10-6/℃), and it has the high thermal conductivity of copper. , its thermal expansion coefficient and thermal conductivity can be adjusted by composition. Both are widely used as integrated circuit, radiator, heat sink material according to needs.

2. Parameter Of Molybdenum Copper Alloy As Microelectronic Material:

|

Thermal conductivity W/(m﹒k) |

Thermal expansion coefficient 10-6/K | Density g/cm3 | Specific thermal conductivity W/(m﹒k) | |

| WCu | 140~210 | 5.6~8.3 | 15~17 | 9~13 |

| MoCu | 184~197 | 7.0~7.1 | 9.9~10.0 | 18~20 |

| MoCu15 | 160 | 7.0 | 10 | / |

| MoCu20 | 170 | 8.0 | 9.9 | / |

| MoCu25 | 180 | 9.0 | 9.8 | / |

| Mo | 138 | 5.35 | 10.22 | 13.5 |

| Cu | 400 | 16.5 | 8.93 | 45 |

![]()

![]()

3. Production craft Of Molybdenum Copper Alloy As Microelectronic Material:

Liquid phase sintering method:

The tungsten-copper or molybdenum-copper mixed powder is sintered in the liquid phase at 1300-1500° after being pressed. The material prepared by this method has poor uniformity, many closed voids, and the density is usually lower than 98%. It can improve the sintering activity, thereby improving the density of tungsten-copper and molybdenum-copper alloys. However, nickel-activated sintering will significantly reduce the electrical and thermal conductivity of the material, and the introduction of impurities in mechanical alloying will also reduce the conductivity of the material; the oxide co-reduction method to prepare powders has a cumbersome process, low production efficiency, and difficulty in mass production.

Tungsten and molybdenum skeleton infiltration method:

First, tungsten powder or molybdenum powder is pressed into shape, and sintered into a tungsten and molybdenum skeleton with a certain porosity, and then infiltrated with copper. This process is appropriate for low-copper-content tungsten copper and molybdenum copper products.Compared with molybdenum copper, tungsten copper has the advantages of small mass, easy processing, linear expansion coefficient, thermal conductivity and some main mechanical properties equivalent to tungsten copper. Although the heat resistance is not as good as that of tungsten copper, it is better than some heat-resistant materials, so the application prospect is better. Because the wettability of molybdenum-copper is worse than that of tungsten-copper, especially when preparing molybdenum-copper with low copper content, the density of the material after infiltration is low, consequently, the material cannot meet the standards for airtightness, electrical conductivity, or thermal conductivity. Its application is restricted.

4. Application Of Molybdenum Copper Alloy As Microelectronic Material:

Molybdenum copper is widely used in integrated circuits, heat sinks and heat sinks and other microelectronic materials. High-power integrated circuits and microwave devices require high electrical and thermal conductivity materials as conductive and heat-dissipating components, while taking into account vacuum performance, heat resistance and thermal expansion coefficient. Tungsten-copper and molybdenum-copper materials meet these requirements due to their properties and are therefore preferred materials for this application.

Molybdenum copper electronic packaging material has excellent thermal conductivity and adjustable thermal expansion coefficient. It is currently the preferred electronic packaging material for high-power electronic components at home and abroad, and can be matched with Be0 and Al203 ceramics. Other industries include those in aerospace, power electronics, high-power semiconductor lasers, and medicine.

In addition, in the fields of microwave packaging and radio frequency packaging, this material is also widely used as heat sink. In military electronic equipment, it is often used as the base material for high-reliability circuit boards.

Please click below button for learn more our products.

![]()